Wice System

DNA of technical expertise and visual language.

From study to technique.

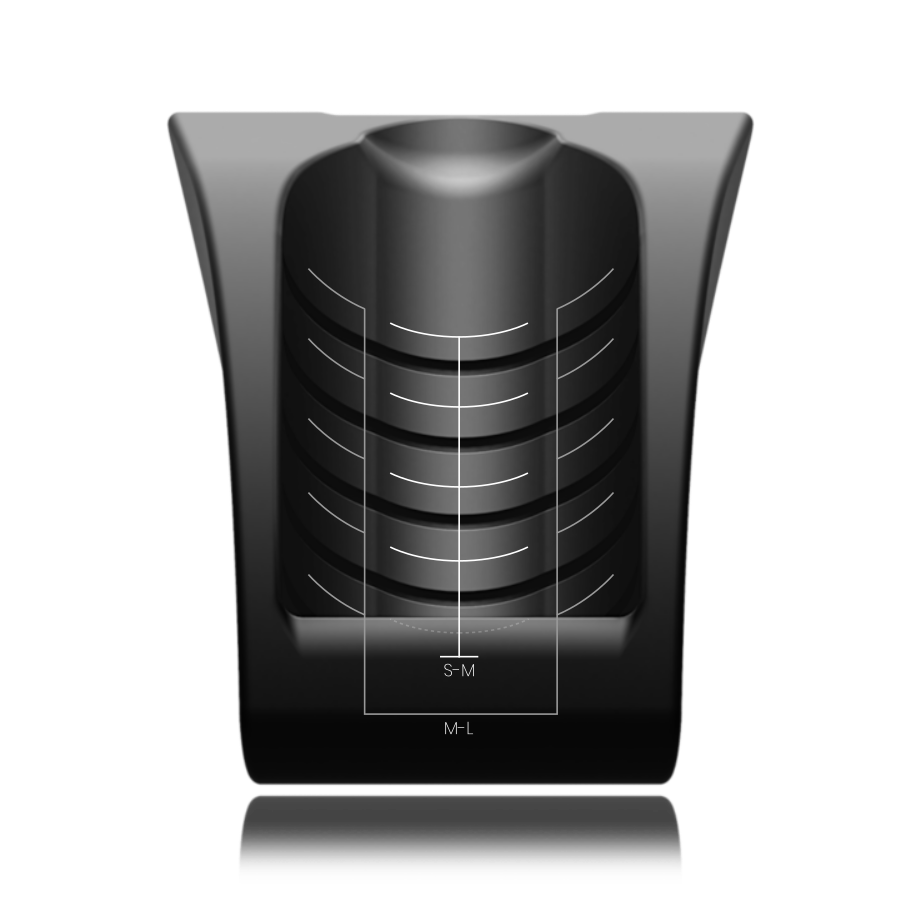

The Wice System cooling unit combines aesthetic and technical solutions to manage the behavior of the cooling liquid inside. The ribbing within the internal cavity preserves the stability of the Wice System during the transition to a solid state in the freezer, while the S-M and M-L curvatures ensure optimal heat exchange with all bottle sizes up to 1.5 litres and a maximum diameter of 105 mm.

Simply placing the bottle will provide the best contact.

– S-M Contact area for small-medium bottles.

– M-L Contact area for medium-large bottles.

Wice System is designed for unlimited use over time and works without water, ice or electricity.

High autonomy,

no water and ice.

The Wice System contains a sealed, non-toxic cooling liquid that, under normal ambient conditions, provides thermal autonomy for up to three hours.

Wice System is designed to reach temperatures down to -30° C, it can be used for either intense or moderate cooling, depending on the wines or beverages to be enjoyed, by preparing it in the freezer or refrigerator.

Harmony between elegance

and technicality.